Cooking oil fume is one of the main sources of volatile organic compounds (VOCS) and PM10 (inhalable particulate matter with particles smaller than 10μm) in the atmosphere. Among the lung cancer-causing factors, cooking oil fume is second only to the danger of “deep smoking” smoke reaching the deep respiratory tract factor.

The National Environmental Protection Administration of China strictly requires the environmental protection bureaus (departments) of all provinces, cities, autonomous regions, and municipalities across the country and the environmental protection bureaus of key environmental protection cities to include the problem of oil fume pollution in the scope of normal environmental management; strictly prohibit the unorganized emission of oil fume pollution sources without ventilation For equipment and purification devices, ventilation facilities and purification devices shall be mandatory. The emission standards shall comply with the “Emission Standards for Cooking Fume (Trial)” (GB18483-2001).

At present, there are mainly the following methods for the purification of kitchen oil fume on the market:

A. Mechanical Oil Fume Purification Equipment

It refers to equipment that uses filtration, inertial collision, adsorption or other mechanical separation principles to remove oil fume purification. The advantages are low price and simple equipment. The disadvantage is that the purification efficiency is low and regular cleaning is required.

B. Wet Scrubber

It refers to the purification equipment that removes oil fume by water film, spray, impact and other liquid absorption principles. Such as our common transport water hood. The advantage is that the price is moderate. The disadvantage is that the purification efficiency is generally less than 60%, and an oil-water separation tank is required, which requires higher daily maintenance.

C. Electrostatic Filter

This type of equipment uses a high-voltage electric field to ionize the passing oil fume, and uses the electric field to attract charged particles to capture the oil mist aerosol in the oil fume. The advantages are high purification efficiency, which can reach 90%-97%, easy maintenance and low operating costs. The disadvantage is the high initial cost. From the analysis of market users, the electrostatic type (including electrostatic compound type) is the most common application, accounting for about 80% of the market, and the wet scrubber and mechanical filter account for about 20% of the market.

What Are the Hidden Dangers from INFERIOR, UNQUALIFIED Electrostatic Filter?

1 Fire Hazards

Since more than 90% of the manufacturers of electrostatic filters do not have the ability to develop products and cannot form the advantage of large-scale production. They also don’t have sound quality inspection system. The electrostatic filters produced are mainly based on imitation without mastering the key technical knowledge. The inferior electrostatic filter can cause fire especially in summer time.

2 Electrical Safety Hazards

Due to the high-voltage current inside the body of the electrostatic filter, if you encounter an electrostatic filter that is without safety protections, there are serious hidden dangers to personal safety. Because inferior electrostatic filters are mainly cost-oriented and electrical safety protection products probably are not installed at all, causing safety problem.

3 Not Able to Purify Cooking Oil Fume

The ” INFERIOR electrostatic filter” may have no effect at all, but increases the resistance of smoke exhaust, resulting in poor exhaust. There was a little effect when it was just installed. After a few weeks, the situation changed significantly.

4 Risk of Forced Closure of Restaurants

Excessive emission of oil fume caused complaints from surrounding residents. As a result, the rectification of oil fume in restaurants was unfavorable and forced closures occurred. It not only wastes manpower and financial resources, but also pays fines from the Environmental Protection Department.

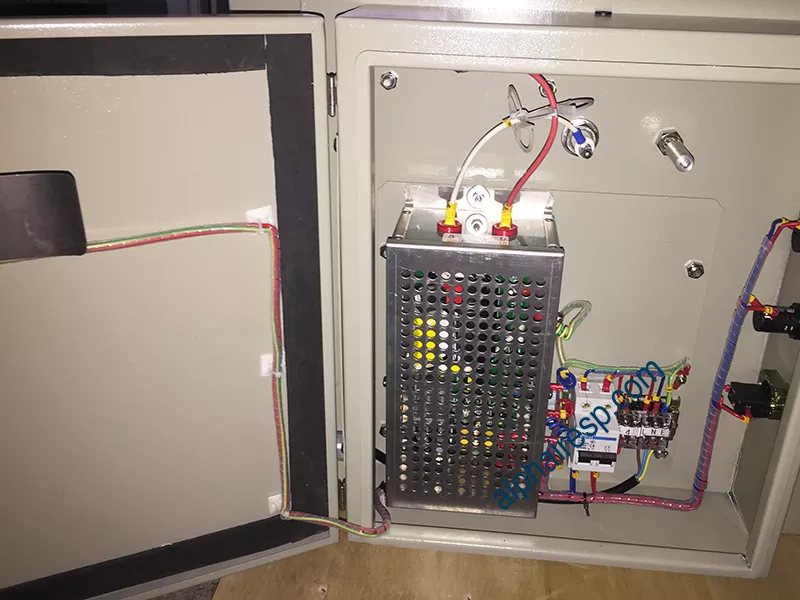

Check Out Superior ALPHAIR™ Kitchen Electrostatic Filter

- Adopting dual purification effects of mechanical separation and electrostatic precipitator technology.

- Easy installation and maintenance.

- Modular design can be combined to a larger air volume.

- Automatically adapt to changes in oil smoke concentration, reliable operation, low noise and long life.

- Compact structure design, small size and light weight.

- Over 95% high fume purification efficiency.

- A5052 aluminum alloy ionizer and collector for long life span.

- Auto power off when ANY door is open.

- Release residual charge on the filter cell automatically when any door is open, higher safety for maintenance.

- 110~240V high-frequency digital power pack with multiple self-protection functions ensure stable & efficient operation.